Asetek Research and Design Centre Tour

September 17, 2010 | 07:32

Asetek Research and Design Centre Tour

Asetek is a name many of you may not be familiar with, though it may ring a bell with some of our more long-term readers and forumites. This is because Asetek used to produce the Vapochill line of enthusiast cooling products that included the mental XE II case, that came with a built in phase-change cooler, and the ill fated Micro Extreme cooler. In 2006 this small Danish company decided to change its focus to producing products exclusively for the OEM market, ceasing its retail presence.The company is probably now best known by enthusiasts for producing the Corsair H50 and H70 coolers, which are based on its proprietary Low-Cost Liquid Cooling (LCLC) concept. It also produces custom variants of its LCLC for system integrators such as Alienware and Acer. The company also produces a number of enterprise-level workstation and server cooling products.

As you can imagine then, we were a little surprised when Asetek invited us over to see its research and design center, which is located in the sunny rural town of Brønderslev in the north of Denmark. Still, we’re never one to pass up a free trip so we jumped at the chance to go and see how Asetek designs, develops and stress tests its products.

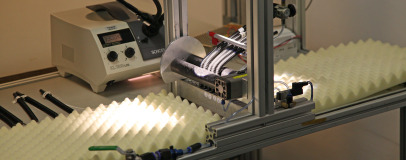

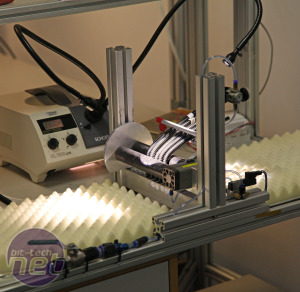

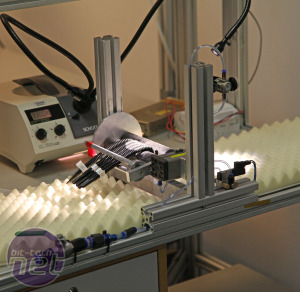

This machine bent the tubing back and forth continually to test the longevity of different materials

One of the first areas Asetek was eager to show off was its tubing development and testing lab. This is because one of the first serious challenges Asetek faced when developing its closed-loop coolers is evaporation. Anyone who owns a water-cooled PC will know that from time to time the loop needs to be topped up. The reason for this is that no matter how watertight your loop, there will always be tiny amounts water escaping from it due to evaporation, be this through the tubing you use or through the connections between your

tubing and components.

Asetek has only just developed the double depth, double fan unit that the new Corsair H70 is based on

Water loss is obviously a serious problem for an closed-loop unit, as performance is likely to degrade over time as water evaporates right up until the point where the unit fails completely. To get around this problem Asetek had to engineer ultra-low-permeability tubing that would allow it to hit its target of 50,000 hours of operational life. The final solution is a trade secret, but Asetek did let on that the plastic it uses has a glass component to it, lowering the permeability of the tubing to the needed levels.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.